Selecting the appropriate bearing shield is crucial for ensuring longevity and reliability in your application. A common point of confusion arises between the 626-2RZ and 626-ZZ types. In this post, we break down their differences and provide a real-world example from our technical support team to guide your decision.

Recently, a customer approached us for support on a new transmission project. While the 626 series bearing was confirmed based on shaft size and pump speed, the choice between metal shields (ZZ) and rubber seals (2RZ) remained unclear due to specific operational conditions.

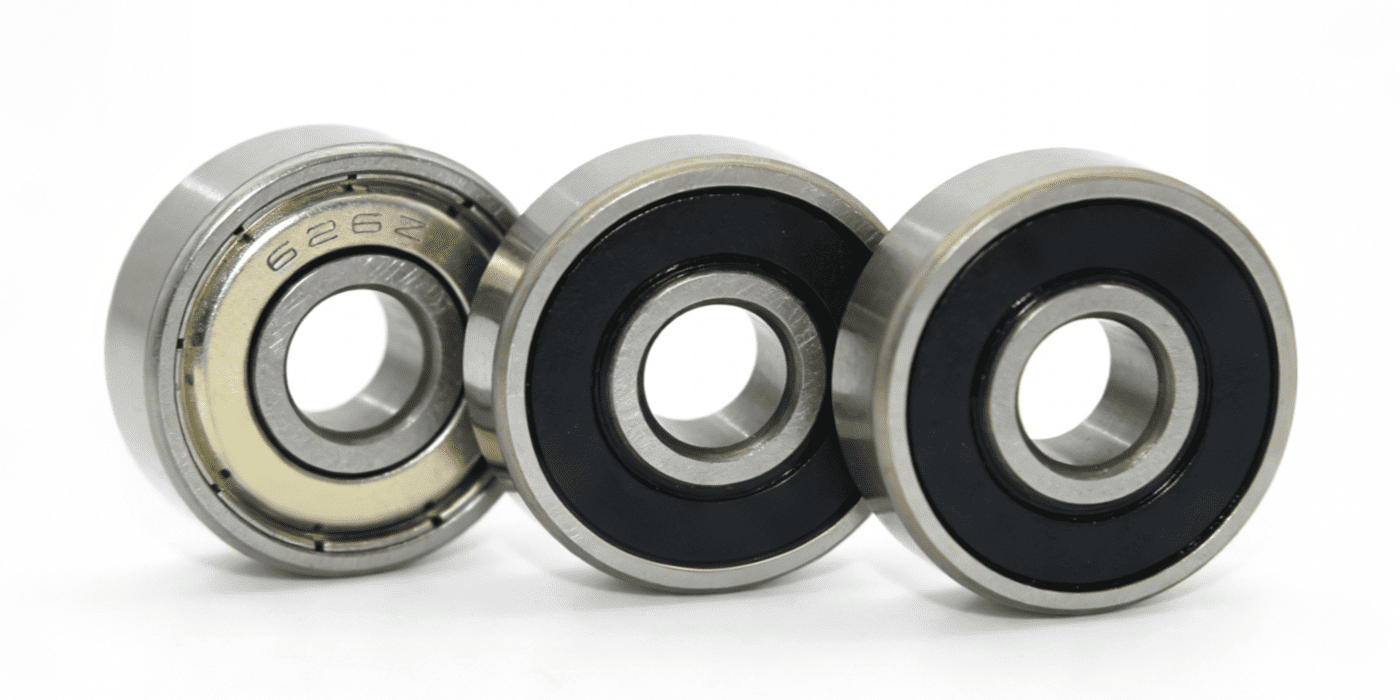

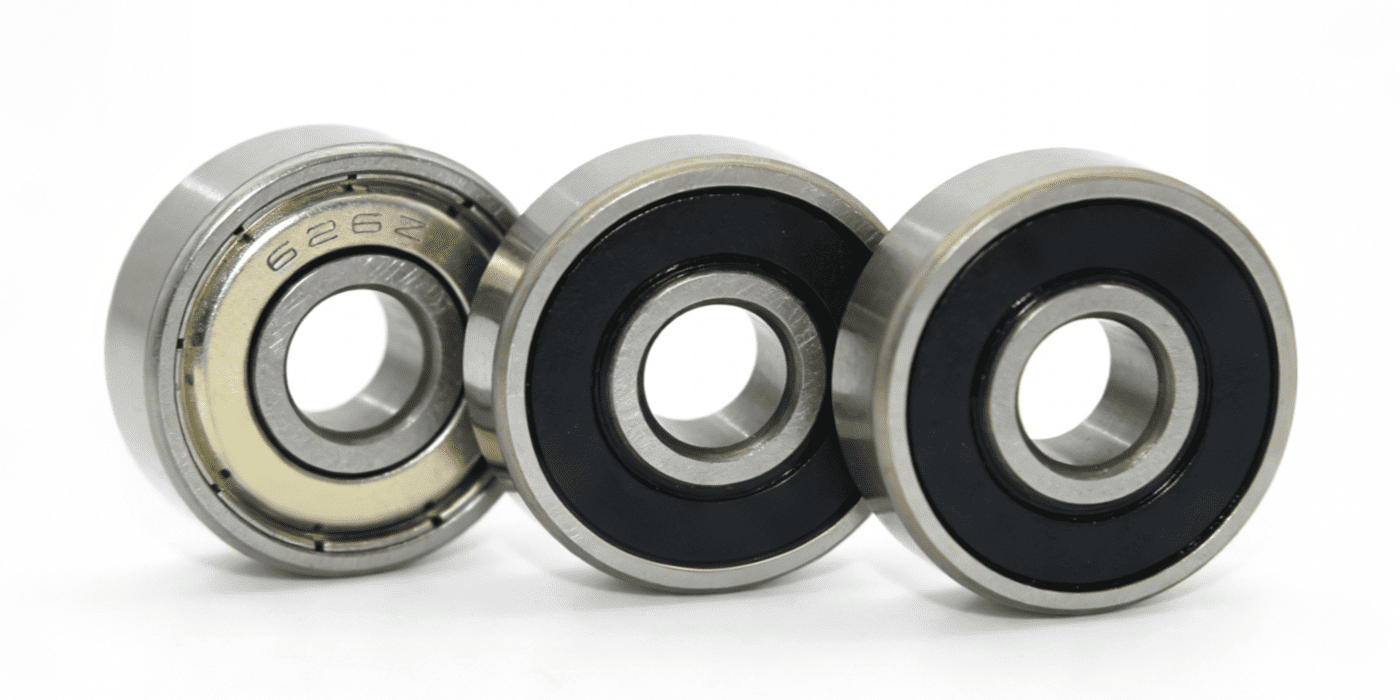

To resolve this, we provided a clear comparison of the two shielding options:

⓵ 626-ZZ (Metal Shield on Both Sides)

Features: Metal shields effectively block larger contaminants like dust but are not a complete seal. They are lubricated once at the factory.

Best For: Clean, dry environments with moderate speeds and light loads.

Typical Applications: Electric motors, fans, and printing equipment where contaminant ingress is minimal.

⓶ 626-2RZ (Rubber Contact Seal on Both Sides)

Features: Rubber seals provide superior protection against dust, moisture, and oils. This comes with slightly higher friction, which can limit maximum operating speed.

Best For: Harsher environments where moisture, oil mist, or fine dust is present.

Given the transmission application's environment, which involved light dust and potential moisture and an operating speed of around 3,500 RPM, our team recommended the 626-2RZ. Its enhanced sealing capability would ensure lower maintenance and higher reliability under these conditions.

The customer accepted our advice and implemented the 626-2RZ bearings, which have since performed excellently in the field. For us, providing the right technical solution is as rewarding as securing the order itself.

When deciding between bearing shields, always consider the operating environment, speed, and load alongside the shaft size. A thorough analysis of these factors is key to selecting the optimal bearing for performance and durability.

Need help specifying the right bearing for your application? Contact our technical team sales@welinkbearing.com today for expert support.